Creepage distance and surface distance of terminal block

Safety precautions for terminal block wiring

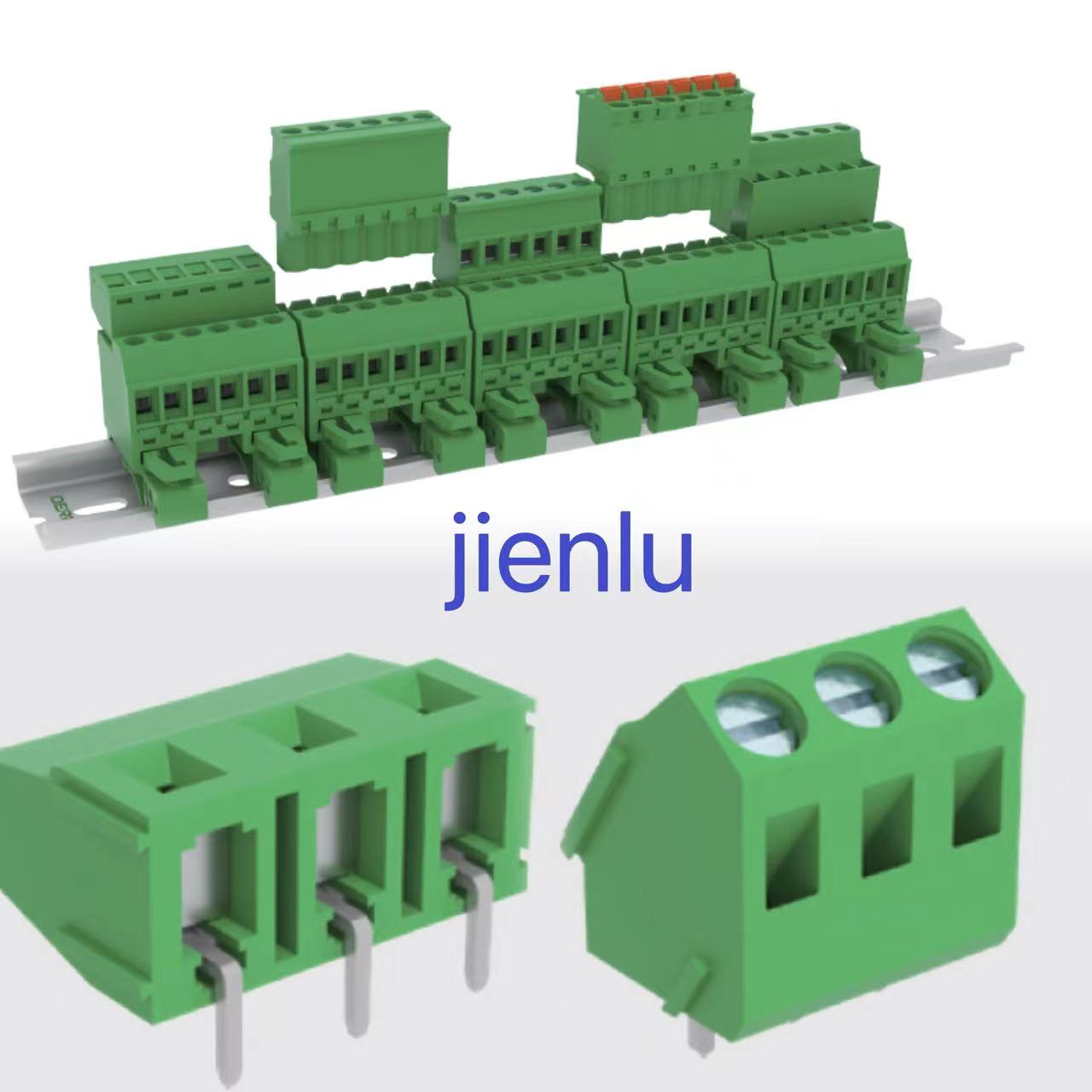

When selecting terminal blocks, creepage distance and clearance distance are crucial safety and performance factors to prevent electrical insulation failure and avoid electric shock or short circuits.

1. Creepage distance: This refers to the shortest path along the surface of an insulating material between two conductive parts. The design of the creepage distance takes into account the insulation properties of the material and the pollution level of the environment. If the creepage distance is too short, it may lead to the formation of an electrical arc along the surface, causing electrical faults or short circuits.

2. Clearance distance: This is the shortest distance between two conductive parts through the air, also known as the air gap. This parameter is important to prevent arcing or breakdown in the air, especially under high voltage conditions. If the clearance distance is insufficient, electric current may cause breakdowns in the air, increasing the risk of electric shock.

The importance of these two distances becomes especially evident in high-voltage applications and harsh environments, as they directly impact the safety, reliability, and durability of the product.

When installing terminal blocks, safety precautions are critical to ensure the safety, stability, and long-term reliability of the equipment. Here are some key safety considerations:

1. Power off before operation: Always ensure the equipment is powered off before performing any wiring or installation to avoid the risk of electric shock.

2. Select the correct terminal block: Choose the appropriate terminal block based on the voltage, current, and application environment, paying particular attention to whether the creepage distance and clearance distance meet the requirements.

3. Cable preparation: Ensure the cable stripping length is appropriate, avoiding lengths that are too long or too short. Exposed wire should not come into contact with other metal parts, which could cause short circuits.

4. Tighten screws: Make sure screws are securely tightened during installation to prevent loosening, which can lead to poor contact or overheating, potentially causing electrical faults or fires.

5. Cable arrangement: Arrange cables neatly to avoid overlapping or tangling. Use cable ties to secure the cables and ensure no mechanical stress or damage is applied to the terminal block.

6.Environmental requirements: Avoid installation in damp, dusty, or high-temperature environments, especially for terminal blocks without protection ratings, as these conditions can lead to insulation failure or corrosion.

7. Regular inspection: Regularly check the fastening and wiring of the terminal block, and promptly address any loose or aging connections to ensure long-term stable operation.

8. Insulation testing: After installation, use an insulation tester to check the insulation performance of the terminal blocks to ensure there is no leakage or insulation damage.

By strictly following these safety precautions, you can effectively prevent electrical accidents and ensure the safe operation of the terminal blocks.